Functionality inspections are painstaking procedures; even a minor mistake can result in weapon failure or worse.

The USAF’s A-10 Thunderbolt II is the first aircraft specifically designed for providing close air support (CAS) for ground forces.

The US and its allies have found its combination of large and diversified ordnance load, lengthy loiter time, precise weapons delivery, austere field capability, and survivability to be vital.

As a result, when CAS is called to fight, the A-10C Thunderbolt II armament systems have no margin for error.

To ensure that the mission of the A-10 is successful, the armament flight of the 355th Equipment Maintenance Squadrons (EMS), which is in charge of loading ammunition and disassembling weapon systems for inspection and cleaning, must guarantee that all systems are fully operational and prepared for use.

“Our jobs as weapons personnel means we cover everything weapon-related including working on the gun system, bomb systems and loading the jet with live ammunition,” Staff Sgt. Justin Fuller, 355th EMS gun section supervisor said.

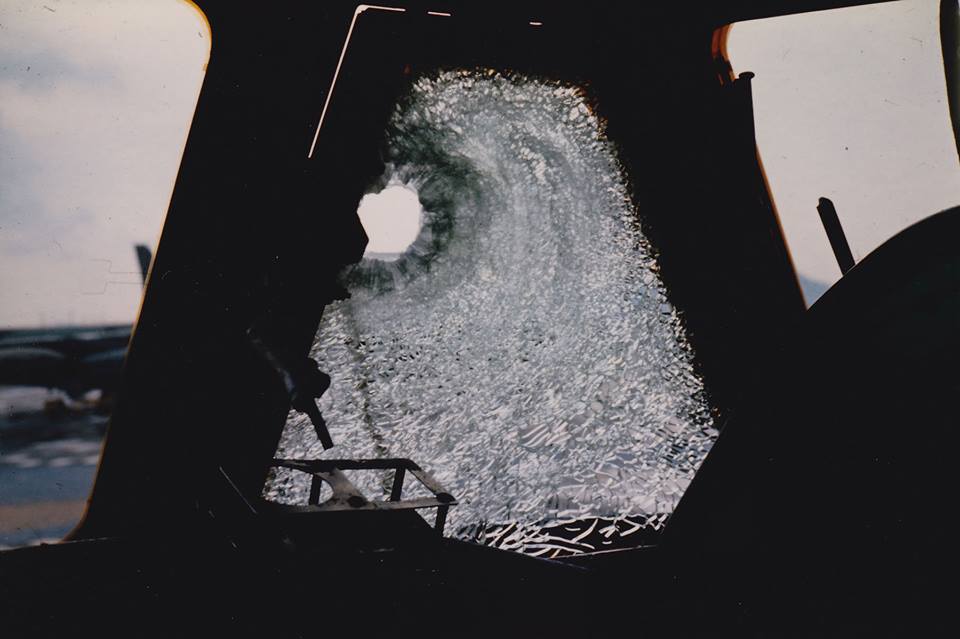

The Hog’s main weapon, the 30 mm GAU-8/A Avenger Gatling gun, has periodic maintenance depending on usage and time. Weapons crew members start by removing panels from the A-10’s nose to its underbelly, completely exposing the gun and all of its parts.

“The 30 mm gun system consists of three components, the Gatling gun itself, the hydraulic drive motor, and the drum which holds up to 1,500 rounds of ammunition,” Fuller commented.

Then the cannon is taken off and given to the armament flight for inspection and cleaning, as described by Master Sgt. Jerrime Williams, 355th EMS armament flight NCOIC: “We inspect it after every 25,000 rounds fired or 36 months. The system comes in, we do a clean, lube it, and change out certain parts.”

The armament flight dismantles the system down to its bare essentials, removes the grease and lubrication, and then leaves a silver gun’s skeleton behind. Before assembling it back, give gears and other moving parts fresh oiling to ensure minimum friction. A final inspection is then conducted.

“We go over every part to ensure there [are] no cracks, rust, or wear and tear,” Williams said.

Functionality assessments are painstaking operations, and even the tiniest mistake might result in weapon failure or worse, “If an inspection isn’t performed correctly, it could put not only our pilots, but our sister services and ground troops in danger,” Williams said.

The cannon is returned to its proper location when the final checks are completed, and the A-10 is ready for its next mission, whether it is in training or war.

The Hog’s large combat radius and quick takeoff and landing capability make it possible to operate in and out of places close to the front lines. The A-10 can loiter near conflict locations for extended periods of time thanks to these unique qualities.

“The A-10 is mainly [used for] ground support which means it is used when our troops are getting shot at,” Fuller said. “When I fully load a jet with bombs and ammo and it comes back with nothing, I feel proud, because I know that what I did was directly involved with saving lives.”

Source: Gunning for Success, Airman 1st Class Ashley Steffen, 355th Fighter Wing, and U.S. Air Force; Photo by Airman 1st Class Ashley N. Steffen and Master Sgt. Scott Thompson / U.S. Air Force